Recycling-friendly design

Flow Pack PurePP and PurePE are designed as a mono-material solution and convincing at the point of sale. Due to their structure as a mono-material solution, the PP- or PE-based Pure-Line films offer the possibility of declaring a high recyclability. You can certify this by external institutes if required.

Our Flow Pack PurePP received the German Packaging Award in 2020 in the sustainability category and was certified by the independent Institute cyclos-HTP with a recyclability of 92 %.*

*The recyclability assessment is based solely on the solutions provided by SÜDPACK and does not automatically apply to customer packaging.

Maximum performance with minimum packaging weight

Flow Pack PurePP and PurePE stand out due to their high level of material efficiency. They offer maximum performance with minimum material input and make significant savings in resources compared to other packaging concepts.

For example, the weight is reduced by 60 % compared to commonly used tray packaging, thus offering economic advantages for you in terms of eco-balance.

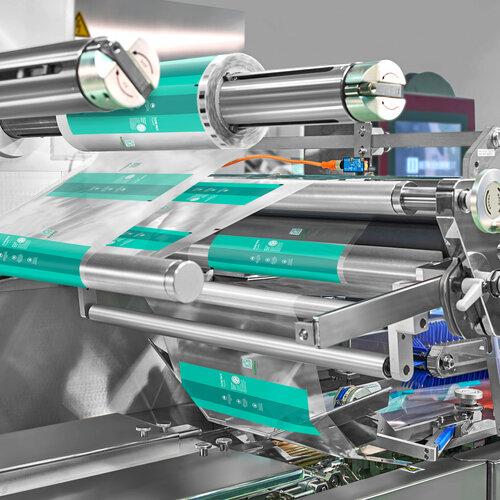

Optimal process and packaging reliability

Equipped with good sealing behavior and a wide sealing range, the films can be processed efficiently on horizontal and vertical flow pack lines even at very high cycle rates of over 100 cycles, resulting for you in high process and packaging reliability.

Maximum safety provided by optimal product protection

Depending on the product requirements you can flexibly equip the high-performance films with different barrier properties for maximum product protection and extended shelf life.

Flow Pack PurePP and PurePE ensure maximum product safety from aroma to oxygen barrier via protection against moisture or UV radiation.

Highly convenient thanks to zipper systems

With different features such as zipper systems, recyclable flow packs can be produced that stand out due to their exceptional level of convenience. As a result, your packing product has a longer shelf life. The structure of the sealing layer ensures the simple and efficient integration of resealing systems based on polypropylene and polyethylene. These are already available on the market for flat pouches and doypacks.

Areas of application

Our high-performance films are ideal for coffee packaging and can be processed into stand-up pouches, flow packs, or vacuum pouches (PP only). Effective barriers against oxygen, water vapor, UV radiation, and nitrogen ensure optimal aroma protection and preserve the quality of this premium natural product. Mono-material valves based on PP or PE can also be reliably integrated via thermal or ultrasonic sealing – in combination with SÜDPACK’s proprietary sealing media.

- Excellent foldability and puncture resistance

- Outstanding sealing properties

- Optimal processability and packaging reliability

The transparent high-performance films with antifog are equipped with a high barrier for maximum product protection and extended shelf life. Thanks to their good sealability, Flow Pack PurePP can be processed reliably on horizontal flow pack machines, even at high cycle rates. Compared to conventional tray packaging, Flow Pack PurePP can also achieve material savings of up to 60 % - an important aspect with regard to internal and external logistics costs along the entire value chain. Above all, however, it is an advantage in terms of eco-balance, disposal costs, and the responsible use of available resources.

- 60 % material reduction

- high process and packaging reliability

- innovative packaging concept scores at the POS

Equipped with good sealability, Flow Pack PurePE for mozzarella applications can be processed easily and quickly, resulting in high process and packaging reliability. Thanks to the excellent puncture resistance and tightness of our packaging, the mozzarella is optimally protected during the entire process, transport and delivery time.

- good sealing seam strength and tightness

- high process and packing reliability

- high puncture resistance

In addition to its recyclability, Flow Pack PurePP for pasta is also highly material efficient. Thanks to the lower material density compared to previously used film solutions, our material offers a striking weight saving. Flow Pack PurePP thus offers ecological and economic advantages.

- high transparency for perfect presentation at the POS

- high barrier for extended shelf life

- suitable for pasteurization applications

More information about recyclable flow pack films

Downloads

Product sheet Flow Pack PurePP

For further information on Flow Pack PurePP, please download our product information sheet.

Product sheet Flow Pack PurePE

For further information on Flow Pack PurePE, please download our product information sheet.