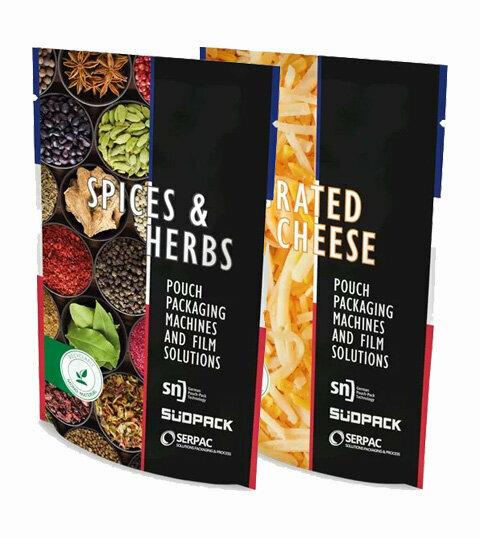

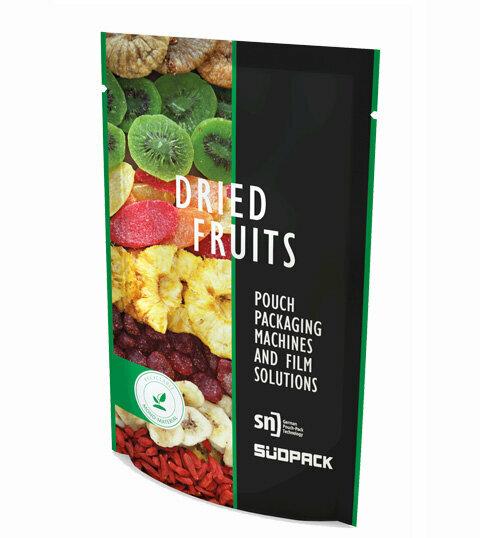

Recyclable flow pack and doypack film solutions

Learn more about our sustainable packaging solutions made from recyclable mono-material.

Recyclable flow pack and doypack film solutions

Learn more about our sustainable packaging solutions made from recyclable mono-material.

Recyclable flow pack and doypack film solutions

Learn more about our sustainable packaging solutions made from recyclable mono-material.

Recyclable flow pack and doypack film solutions

Learn more about our sustainable packaging solutions made from recyclable mono-material.

Recyclable flow pack and doypack film solutions

Learn more about our sustainable packaging solutions made from recyclable mono-material.

Recyclable flow pack and doypack film solutions

Learn more about our sustainable packaging solutions made from recyclable mono-material.

contact

Would you like to learn more? We will be happy to advise you.