Our overall concept for the in-house production of spouted pouches sets standards in economic profitability and sustainability

SÜDPACK has joined with SN Maschinenbau and MENSHEN to break new ground in packaging with spouted pouches. The partnership comprised of three industry leaders sets standards in economic profitability and sustainability. Together, we are presenting our pioneering solution for the in-house production of recyclable spouted pouches, which are also suitable for hotfilling and pasteurization.

The recyclable mono-material solution is based on polypropylene. All three components – film, spout and pouch packaging machine – are perfectly coordinated to work together. This ensures efficient processing and optimal packaging reliability, even for demanding applications such as hotfilling or pasteurization.

Reduce your packaging costs by producing your own spouted pouches – without making any compromises in quality or packaging reliability.

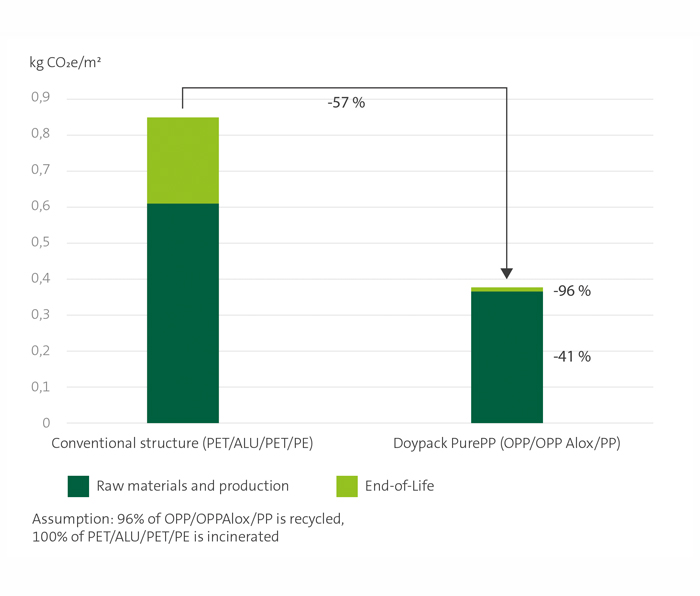

Recyclable PurePP film solution for spouted pouches

Safe processing and high process reliability

Our film solution for spouted pouches offers a wide processing window and is perfectly matched to the spouts from MENSHEN. This provides high process efficiency as well as the reliable sealing in of spouts with optimal output. The excellent sealing strength ensures the outstanding tightness and burst-pressure resistance of the filled pouches.

Optimal product protection and shelf life

The PP-based film from SÜDPACK is equipped with a high barrier, which ensures optimal protection for products. Thanks to their heat resistance, they are ideal for hotfilling and pasteurization. Moreover, the barrier properties of the film can be customized to suit the requirements of the product to be packaged.

Download product data sheet

Contact us

Advantages of the overall concept for spouted pouches

Economic profitability and handling

Reduce the costs of packaging by producing your own spouted pouches. This results in high efficiency gains that make the investment in a pouch packaging machine highly attractive from an economic point of view. With a full return on investment in less than one year, this overall solution offers an unparalleled economic aspect. Furthermore, this eliminates the complex handling and logistics that are usually involved in the processing of finished pouches. The spouted pouches are filled as usual on standard filling lines.

Product safety and product protection

Perfectly coordinated components guarantee a high level of safety for the package and therefore protection for the product.

Simple process

The pouch packaging machine is extremely user-friendly. Due to how easy it is to use, it can be operated by the existing staff. As a result, the insourcing of pouch production for your company does not lead to additional costs. The reel change has to be performed at most once every shift. After pouch production, your spouted pouches are simply transferred to the filling line and filled as usual.

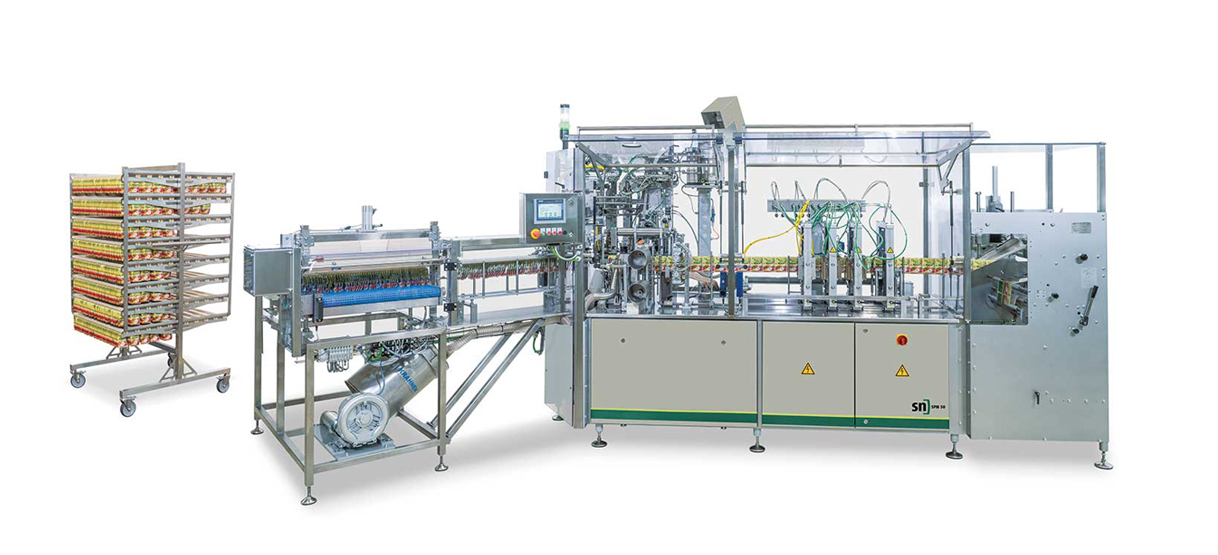

Smart SN machine technology for spouted pouches with added value

For the production of spouted pouches from roll stock material, the horizontal SPM 50 pouch maker from SN Maschinenbau is the perfect choice. The finished pouches are automatically inserted into commercially available rail systems and stored on a transport cart. During the ongoing process, the rails can be easily and ergonomically inserted into pouch-filling machines for filling. This provides a real advantage in terms of efficiency and throughput compared to pre-made pouches, because it eliminates the time-consuming process of unpacking and separating the rails. This makes the standard deposit system for rails and end caps obsolete.

The packaging concept also offers guaranteed pouch quality, flexibility and value creation in your company while reducing the amount of storage space that is necessary. Overall, the compact SPM 50 can achieve a throughput of up to 4,200 pouches per hour and over 30,000 spouted pouches from just one film reel per eight-hour shift. This results in an annual production volume of seven million spouted pouches in one-shift operation or up to 21 million in three-shift operation.

Spout MENSHEN LoTUSTM – the optimal and efficient weld

The MENSHEN LoTUSTM, which has been coordinated with machine manufacturers, is based on a recyclable mono-material solution. It can be optimally connected to the pouches due to the optimization of the heat distribution and conductivity in the spout. When used correctly, this saves energy and ensures an optimal production process and does not have any impact on machine capacity. The spout stands out not only due to its improved sealing quality, but also due to the improved appearance of the sealed area.